Van Meeuwen

Well-oiled service thanks to service design

The importance of lubrication maintenance

Good lubrication is the foundation of all machinery. It yields cost savings and more uptime. Compare it to your bicycle. If the chain never receives a drop of oil, we all know what will happen. The bike will squeak and grind, and on an unlucky day the chain will break. By then, the gears and ball bearings will have to be replaced as well. Lots more annoying, and expensive, than a regular drop of oil.

Challenge for the future

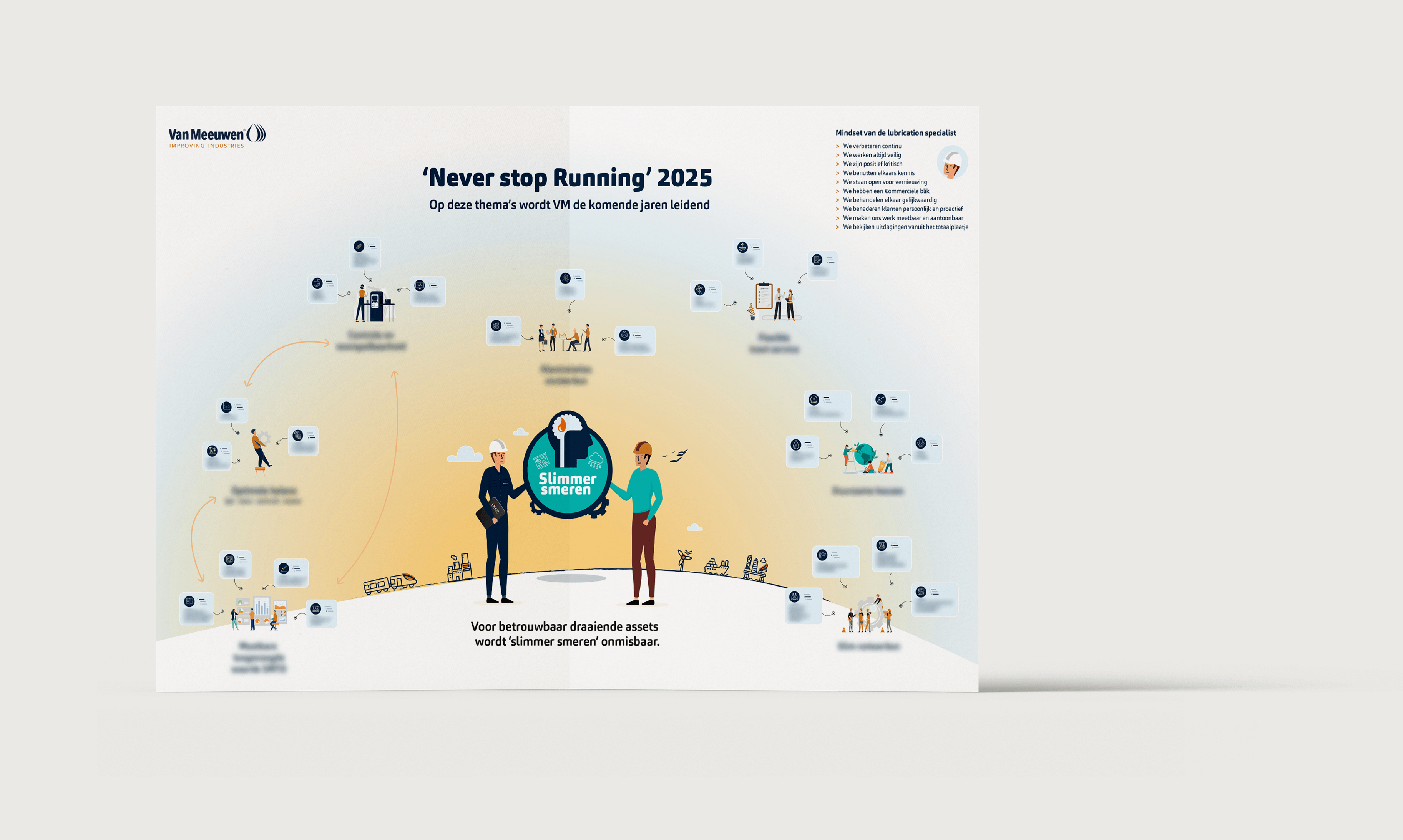

There is much to be gained in lubrication maintenance, especially when mutual knowledge is better utilized. The question is therefore: 'How do you change the 'mindset' of maintenance managers of production facilities so that they are prepared to provide insight into their maintenance data?' And to share that data with Van Meeuwen, so that an optimal solution is created? And how do you keep developing the organization to be a knowledge partner? Van Meeuwen approached us with this issue. This case shows what customer-oriented design, visualization and co-creation yield. How design helps to initiate successful change. We are therefore proud of the results achieved.

Investigating

Together with Van Meeuwen we started the exploration, looking for the latent client desires. We frequented the factory. Asking questions, asking further, and another control question. On the verge of irritating. Validating every finding and supposition. We used an inexhaustible source of experience and knowledge: the Van Meeuwen employees. Not just to ensure that the right information will submerge, but also to create support for change.

What we have learned

The maintenance manager is responsible for lubrication maintenance. But in the work day’s hustle and bustle maintenance is never ‘top of mind’. The manager also struggles to justify investments in lubrication, because the direct value is not visible. While there can be much gain in a more expensive lubricant, or more lubrication, or a better trained technician. One hour downtime less, replacing less parts, or a year of extra life span, can amount to tens of thousands euros. Plus, not unimportant these days, it adds to a more sustainable business. All these results speak for themselves, but only after they are made visible in figures and improvement plans. The people who make the decisions also have to understand why it’s wise to invest.

Concept development

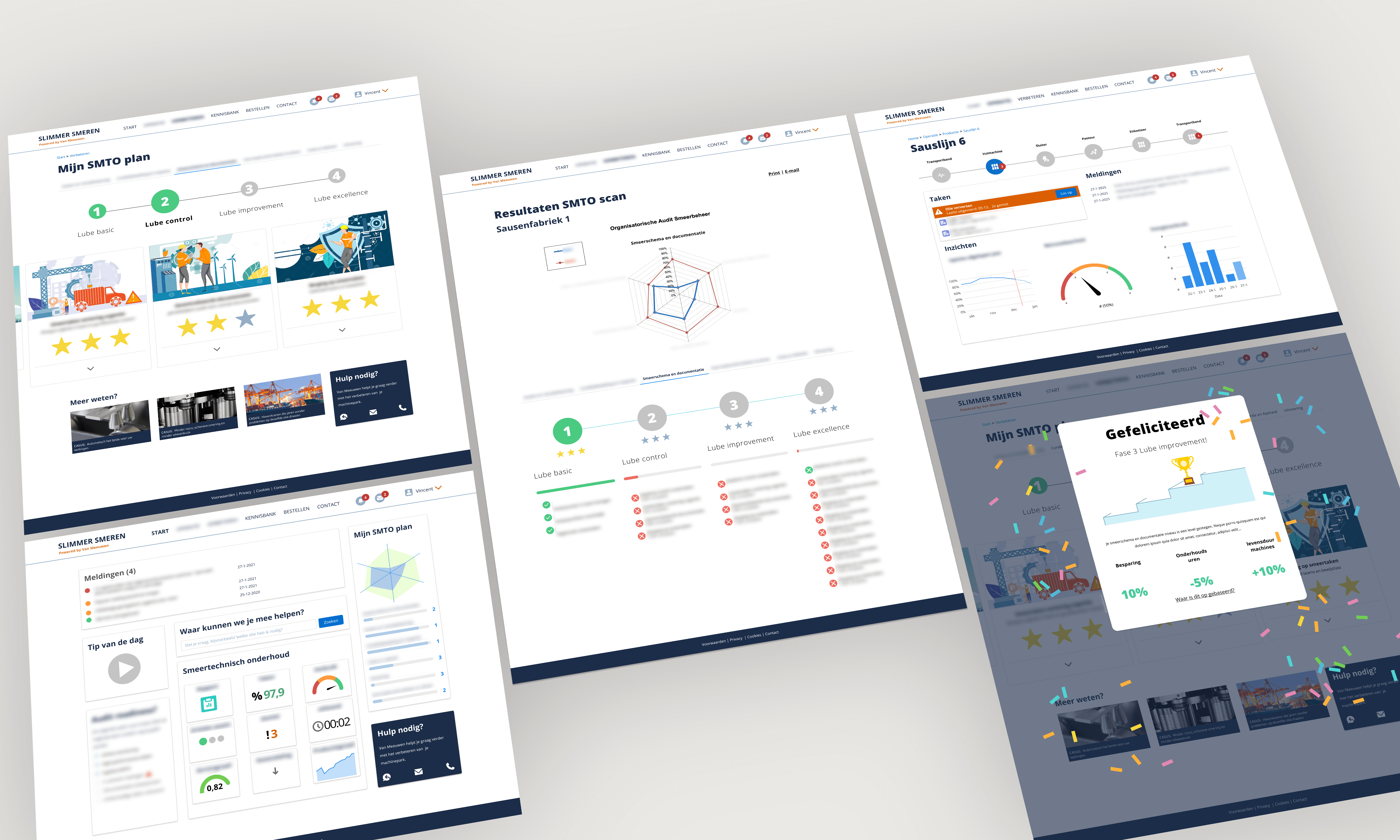

Using the input from the investigation, we conceived several ideas and brought them to life in scenarios, proposition pages and clickable prototypes. The visualizations helped to make the first ideas tangible, in order to look into the future.

Experimenting

The concepts may be beautiful, but do they make the client happy? Only by testing in practice you can discover whether a solution really works. To validate the most risky suppositions, we thought up some experiments to ensure the clients really value the solutions.

The result

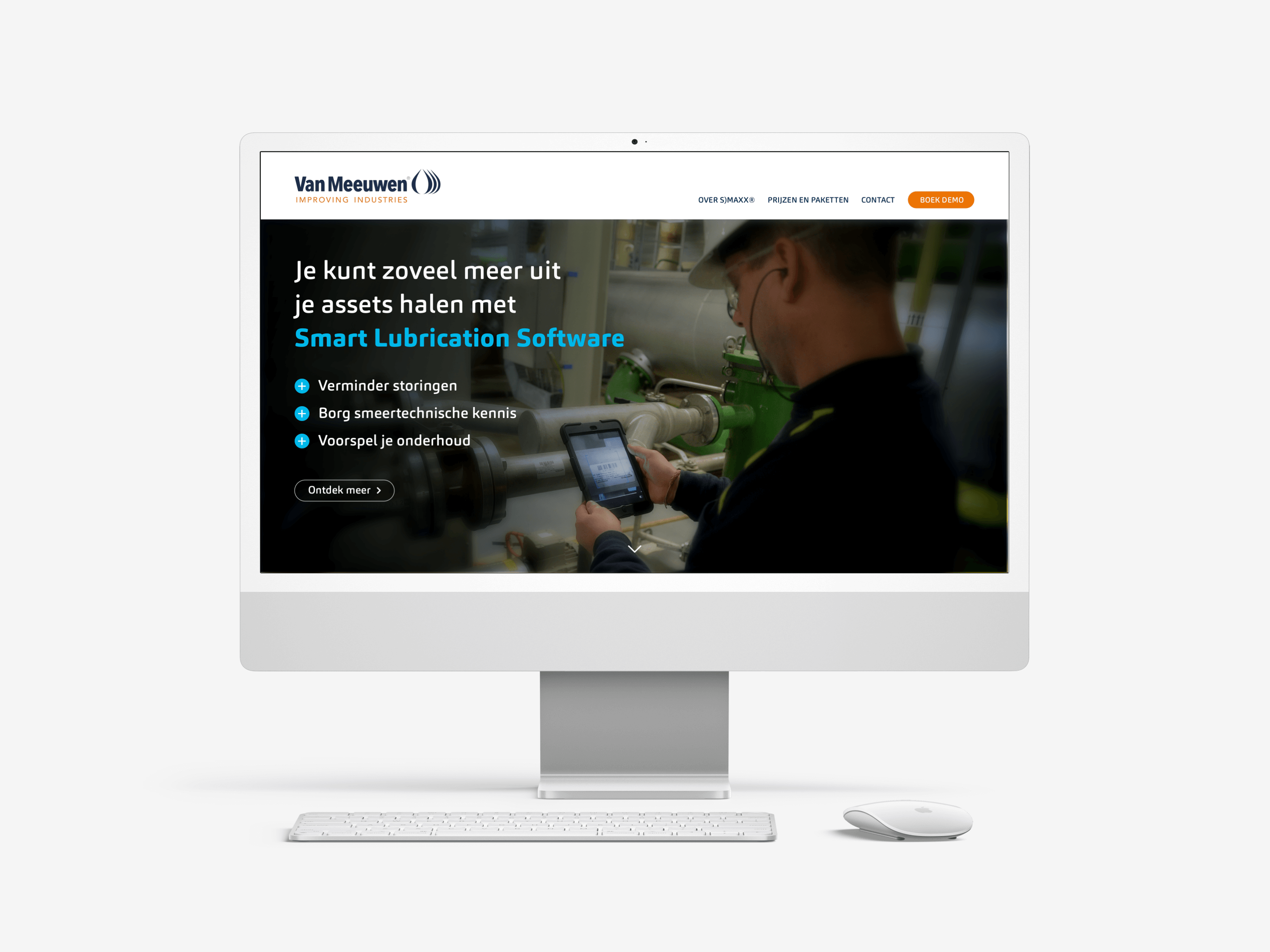

Together, we created value on several fronts. We have developed a future vision, and brought it to life in two validated propositions for digital lubrication maintenance. The vision was named ‘Smarter Lubrication Maintenance’, because that’s how it should be: simple and smart. The ‘Smarter Lubrication Maintenance’ platform and a software tool make this vision concrete. The tools provide insights in the possible improvements in lubrication maintenance, and ensures that the team involved can take the right action at the right time. This way, the added value of better lubrication maintenance is made tangible. It helps the maintenance manager to justify investments and to implement effective improvements. After a successful pilot phase, the platform is being rolled out to 40 clients.

A change in the organization

But the main profit might be just this: Van Meeuwen has adapted to a new way of working, using customer-focused design, experiment and validation. That’s a big change in the mindset of the organization and its employees. We achieved this by actively involving the employees and teaching them the ‘tricks of the trade’ in co-creation sessions and excersises, like our Masterclass Service Design. Which fits the Informaat adagium ‘demonstrate-participate-selfmade’. Van Meeuwen keeps improving itself and is all set for a future as high-end service proivider and expert in lubrication maintenance.

"I'm not only impressed by the result of this service design collaboration, but also by the way Informaat took care that our employees have adopted a new, client-driven way of thinking. This is of permanent value to the organization."

Rogier van Meeuwen

Ook .....

Marcel Kosters

Business director